Pipe Distribution Systems – Pds

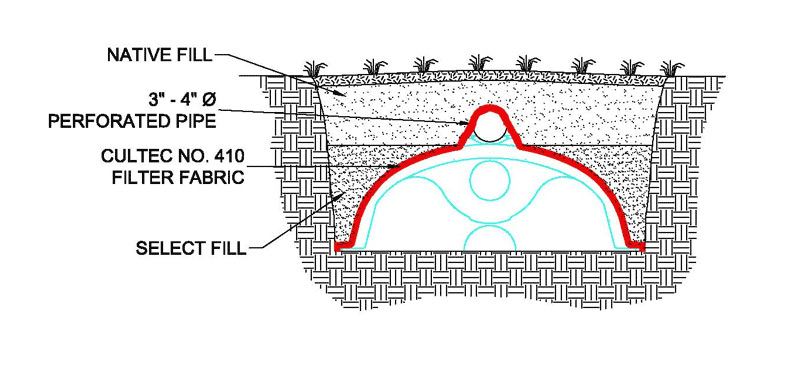

CULTEC promotes the placement of perforated pipe along the top of the outside of their septic chambers. A filter fabric covering is then placed over the pipe and chamber. This method of installation is called a pipe distribution system or PDS system.

Wastewater is discharged through the perforations of the pipe directly onto the filter fabric. The filter fabric works as a sponge and absorbs the effluent and increases the total surface area of the septic system through capillary action. Overall concentration of effluent per square foot is thereby decreased.

When the pipe is on top of the unit, the suspended solids settle out on the outside of the chamber between the fabric and the sidewall bottom of the unit. This allows for the open bottom within the chamber to perform at maximum effectiveness since it is not being contaminated by the settling out of particles.

The effectiveness of the primary leaching base area is increased by allowing suspended solids to settle on the outside of the chamber rather than contaminating the open bottom area beneath the chamber.

A PDS system may either be a gravity system that relies on gravity to distribute the effluent or may be a pressure distribution system that employs a lift station with a pump to dispense the wastewater to the leachfields.

Benefits:

- Overall contact area is increased

- Primary leaching area is not contaminated

- Effectiveness of leaching area is maximized

Shows perforated pipe on top of CULTEC septic chamber covered by CULTEC No. 410 filter fabric.

Shows perforated pipe on top of CULTEC septic chamber covered by CULTEC No. 410 filter fabric utilizing a lift station to pump the effluent.

We are able to assist you in your design by performing preliminary calculations and supplying AutoCAD layouts free of charge